HP DRY CCSPROCESS

The HP-Dry CCS presents a continuous process for dry conveying of powdered coal or a blend of bulk solid dry carbonaceous material subject to partial oxidization whereby the conveying feed will be conveyed via a suitable conveyer from a atmospheric silo to a or a number of extruder’s funnel(s) and fed in continuo to a or a number of extruder(s), in which the powdered feed material will be densified along the compression zone of the extruder up to high pressure and shall be discharged into a downstream said First Pressurized Vessel, wherefrom the feeding material has to be transported via a pressurized tubular drag conveyor to the said Second Pressurized Vessel, which is equipped with one or more Reactor-Feeding Unit(s) each one consisting of a Discharge Star Valve, Reactor-Feed-Line and an Injection-Line individually, whereby the feed carbonaceous powder will be injected with an injection gaseous media (saturated steam, superheated steam, inert gases, natural gas or a blend of those gaseous media in any composition) by the way of pneumatic bulk conveying into a downstream pressurized gasification reactor and chemically converted under high temperature and elevated pressure by partial oxidization to syngas gas, slag and ashgas gas, slag and....

Download Files

High Pressure Dry Continuous Coal Supply

Option 1

Option 2

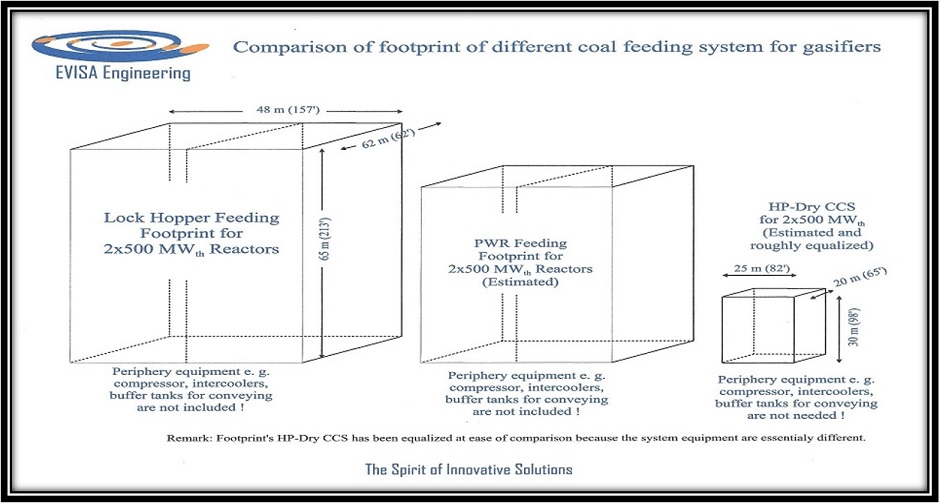

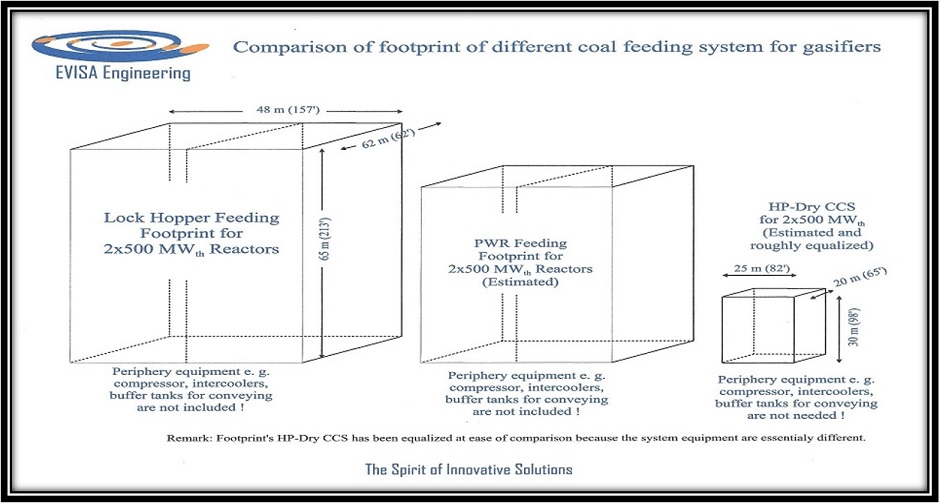

Footprint Comparison